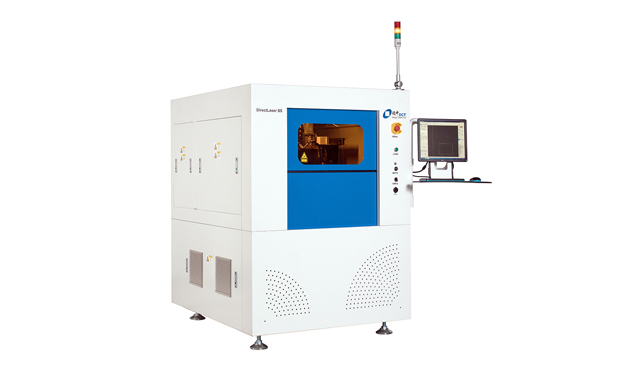

DirectLaser U5 Laser Multifunctional Microfabrication Equipment

DirectLaser U5 is a classical U-series model, which adopts classical bridge structure, i.e. X-axis and Y-axis separated motion structure. The processing head moves around X-axis on stable bridge, and the workpiece clamping table moves around Y-axis. The two systems are independent, and their respective movements do not interfere with each other.

Features

Precise laser control

Precision drilling micro holes

Unification of Multi-functional

High quality ceramics cutting

Perfect in micron level

Product parameters

Technical data | DirectLaser U5 |

Laser wavelength | 355nm |

Repetitive accuracy | ≤±2μm |

Scan field X/Y resolution | 1μm |

X/Y resolution | ≤0.5μm |

Working area | 520mm x 500mm |

Data acceptance | Gerber, HPGL, Sieb & Meier, Excellon, ODB++, DXF |

Platform structure | Granite table, bridge |

Dimension (W x H x D) | 1,560mm x 1,250mm x 1,915mm |

Weight | Approx. 1,500kg |

Operating ambient | DirectLaser U5 |

Power requiements | 380VAC/50Hz, 3kW |

Ambient temperature | 22℃±2℃ |

Configuration and options | DirectLaser U5 |

Data processing software | CircuitCAM 7 |

Machine operating software | DreamCreaTor 3 |

Automatic feeding | Optional |

Online laser power measurement | N/A |

Laser height measurement | Optional |

Camera automatic positioning | Included |

Exhaust unit | 210mᵌ/hr, 220V, 1.5kW |

Workpiece fixture | Vacuum table, customizable fixture |

FFU positive pressure cleaning device | N/A |